Shop By Category

- Hot Deal

-

Neodymium Magnets

- Neodymium Magnets

-

DISC Magnets

- DISC Magnets

- Disc Neodymium Magnets Diameter <= 1/4"

- Disc Neodymium Magnets 1/4 < Diameter <= 1/2"

- Disc Neodymium Magnets 1/2 < Diameter <= 1"

- Disc Neodymium Magnets Diameter > 1"

- Cylinder Magnets

- Diametrically Magnetized Magnets

- Countersunk Disc Magnets

- Adhesive Disc Magnets

- Plastic Coated Disc Magnets

- Steel Magnet Strikers

- BAR Magnets

- RING Magnets

- CUBE Magnets

- ARC Magnets

- WEDGE Magnets

- Magnet Sphere

- N52 Neodymium Magnets

- CERAMIC Magnets

- SmCo Magnets

- ALNICO Magnets

- Cup & Pot Magnets & Magnetic Bases

-

Home Magnets

- OFFICE Magnets

- Industrial Magnets

- Magnet Wires

- Neodymium Magnets Catalog

- Amazon Neodymium Magnets

- Custom Made Magnets

- WIND POWER - Blades

Shop By Brand

- Neodymium Magnets

-

DISC Magnets

- DISC Magnets

- Disc Neodymium Magnets Diameter <= 1/4"

- Disc Neodymium Magnets 1/4 < Diameter <= 1/2"

- Disc Neodymium Magnets 1/2 < Diameter <= 1"

- Disc Neodymium Magnets Diameter > 1"

- Cylinder Magnets

- Diametrically Magnetized Magnets

- Countersunk Disc Magnets

- Adhesive Disc Magnets

- Plastic Coated Disc Magnets

- Steel Magnet Strikers

- BAR Magnets

- RING Magnets

- CUBE Magnets

- ARC Magnets

- WEDGE Magnets

- Magnet Sphere

- N52 Neodymium Magnets

Shop By Brand

BAR Magnets

Neodymium Bar Magnets: Strength and Versatility for Every Application

Neodymium Bar Magnets, also recognized as Neodymium Block Magnets or Rectangular Magnets, offer an unparalleled range of magnetic grades, from N35 to N52, catering to a wide spectrum of industrial, commercial, and personal applications.

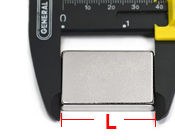

Size and Strength to Meet Every Need

Our expansive selection of Neodymium Rectangle Magnets spans lengths from 1/8" to 8", equipped with pull forces ranging from a modest 0.36 LB to a formidable 600 LBs. Each magnet grade is meticulously designed to endure specific maximum operating temperatures, guaranteeing superior performance across diverse settings.

Engineered for Maximum Magnetic Force

Featuring Residual Magnetic Flux Densities between 11,500 and 14,400 Gauss (1.15 to 1.44 Tesla), these magnets epitomize magnetic strength. Our Neodymium Bar Magnets are not just strong; they're designed to deliver exceptional magnetic power, ensuring reliability and efficiency in every use.

Durability and Corrosion Resistance

The resilience of our Neodymium Bar Magnets is enhanced by a strong Ni+Cu+Ni triple-layer coating, with additional options including epoxy and plastic encasements for increased durability and corrosion resistance. This makes them ideal for a multitude of applications, from secure fastening and lifting to inventive and creative projects.

Versatile Applications of Strong Neodymium Bar Magnets

Whether you're undertaking a complex industrial task, engaging in a lifting operation, or exploring creative avenues, our Permanent NdFeB Neodymium Magnets are proof of reliability and strength.

1. What Are Neodymium Bar and Block Magnets?

Neodymium Bar and Block Magnets, comprising a high-performance Neodymium-Iron-Boron (NdFeB) alloy, represent the high level of permanent magnet technology. Characterized by their significant magnetic strength and rectangular configuration, these magnets are engineered to meet the demanding requirements of various applications.

Principal Characteristics:

- Magnetic Strength: Ranking among the most potent permanent magnets available, Neodymium Bar Magnets are crucial for applications requiring high magnetic force.

- Form Factor: Available in bar or block geometries, these magnets offer versatility in integration and use across a multitude of industrial and scientific contexts.

- Application Versatility: Employed extensively in sectors such as magnetic separation, electrical machinery, healthcare, and research, these magnets fulfill critical roles in enhancing performance and efficiency.

- Customization Capability: Neodymium Bar and Block Magnets can be precisely tailored in size and magnetic properties to suit specific project requirements, underscoring their adaptability.

- Magnetic Grades: Available in a range of grades (e.g., N35, N42, N52), these magnets are classified based on their maximum energy product, facilitating selection based on application-specific magnetic strength requirements.

In conclusion, Neodymium Bar and Block Magnets are integral to advancements in numerous fields, attributed to their exceptional magnetic properties and the ability to be customized for specialized applications. Their use spans a wide array of technological, industrial, and scientific endeavors, making them indispensable.

2. What Are the Common Uses of Neodymium Bar and Block Magnets?

Neodymium Bar and Block Magnets, notable for their superior magnetic properties, are integral to the functionality and advancement of various sectors. Fabricated from an NdFeB alloy, these magnets are distinguished by their high magnetic strength and versatility for numerous applications.

Key Industrial and Technological Applications:

-

Magnetic Separation: Utilized extensively in mining, food processing, and recycling, Neodymium Bar Magnets are crucial for the removal of ferrous contaminants, ensuring the integrity and quality of materials.

-

Electric Motors and Generators: Fundamental in the operation of electric motors and generators, these magnets generate magnetic fields essential for the conversion of electrical energy to mechanical energy, and vice versa.

-

Magnetic Therapy Devices: In the healthcare sector, Neodymium Bar Magnets are employed in devices designed for pain relief and healing, indicative of their diverse utility beyond industrial applications.

-

Research and Development: Supporting scientific exploration, these magnets are used in laboratory settings for the investigation of magnetic phenomena and in the development of new technologies.

-

Secure Fastening Solutions: Their strong magnetic pull makes them ideal for secure closures in consumer products, from personal accessories to household cabinetry.

-

Educational Tools: Serving as practical aids in the demonstration of magnetic principles, these magnets enhance the educational value of science curriculums.

-

Organizational Tools: Leveraged for organizational purposes, they assist in maintaining orderly environments in both domestic and professional settings.

-

Innovation in Arts and Crafts: Artists and designers incorporate these magnets into creative projects, showcasing their application in the arts.

-

Automation and Robotics: Critical to robotics, Neodymium Magnets facilitate precision and efficiency in automated systems and robotic operations.

Neodymium Bar and Block Magnets are indispensable across a variety of industries, from their core roles in manufacturing and technology to innovative uses in healthcare, education, and the arts. Their unmatched magnetic strength and adaptability underscore their importance in driving efficiency, innovation, and development across diverse fields.

3. What Are the Different Grades of Neodymium Magnets?

Neodymium Magnets are distinguished by a grading system that categorizes them based on magnetic properties, including magnetic strength, durability under various temperature conditions, and resistance to demagnetization. This system is essential for selecting the appropriate magnet for specific industrial, scientific, or technological applications.

Detailed Grades of Neodymium Magnets:

-

Standard Grades (N35 to N52): This range signifies the magnet's maximum energy product, with N52 representing the highest available magnetic strength within standard temperature conditions. These grades are utilized extensively in applications where high magnetic force is essential.

-

Lower Grades (N30 to N33): Characterized by comparatively weaker magnetic properties, these grades are suited for applications where moderate magnetic strength suffices.

-

High-Temperature Grades (N28EH to N35EH, N28UH to N35UH): Specifically engineered to retain magnetic properties at elevated temperatures, these magnets are indispensable in environments where thermal stability is critical.

-

High Coercivity Grades (N28SH to N45SH, N28AH to N35AH): Designed to resist demagnetization, these grades are preferred in applications requiring sustained magnetic performance under stress or in adverse conditions.

-

Custom Grades: Beyond the standardized grading, Neodymium Magnets can be custom-fabricated to meet unique performance criteria, offering solutions tailored to specific project demands.

Application Considerations

Selecting an appropriate Neodymium Magnet grade involves analyzing the application's requirements, including needed magnetic strength, exposure to temperature extremes, and potential demagnetizing forces. This careful consideration ensures the magnet's performance aligns with the application's demands, thereby optimizing functionality and reliability.

4. Are Neodymium Bar and Block Magnets Safe to Handle?

Neodymium bar and block magnets, known for their exceptional power as strong bar magnets and powerful bar magnets, must be handled with care due to their significant magnetic strength. Below are essential safety tips to ensure proper handling of these neodymium bar magnets:

- Pinching Hazard: The intense magnetic force of neodymium bar magnets makes them capable of quickly attracting and pinching objects or body parts. It is crucial to keep fingers and other body parts away from the space between these magnets to avoid injuries.

- Collision Risk: Neodymium bar magnets can collide with great force when they come into contact with each other, possibly causing them to shatter or break. This may result in sharp fragments and flying debris. Maintain a safe distance between magnets to mitigate collision risks.

- Swallowing Hazard: Due to their small size, neodymium bar magnets pose a swallowing hazard, particularly for children. If swallowed, these magnets can attract through intestinal walls, leading to severe complications. Always store these magnets out of reach of children and pets.

- Skin and Eye Safety: Unexpected snapping of neodymium bar magnets can cause skin injuries or bruises. Additionally, fragments or dust from broken magnets may cause eye irritation or damage. Safety goggles and gloves are recommended when handling these magnets.

- Protective Packaging: Proper packaging and separation of neodymium bar and block magnets are essential during storage and transport to avoid unintentional attraction and potential damage.

- Handling in Pairs: Managing these magnets in pairs can provide better control over their movement and reduce the risk of unexpected attractions, enhancing safety during handling.

- Demagnetization: Exposure to high temperatures or strong external magnetic fields can demagnetize neodymium magnets. It's important to be aware of their temperature limits and avoid exposure to strong magnetic fields.

In conclusion, while neodymium bar and block magnets are invaluable for various applications due to their strength as neodymium bar magnets, they require meticulous handling to prevent accidents and ensure safety. Following these guidelines will help maintain both your safety and the integrity of the magnets.

5. Can Neodymium Magnets Be Customized in Size or Shape?

Neodymium magnets, particularly powerful bar magnets and strong bar magnets, can be customized in size and shape to meet specific requirements. Customizing neodymium bar magnets allows for optimal performance in various applications, making them a flexible solution for unique needs.

Here are some essential aspects to consider when customizing neodymium bar and block magnets:

- Tailored Dimensions: Customize your neodymium bar magnets to any desired size and shape. Whether you need compact, powerful bar magnets or larger block magnets, precise customization is possible to suit your specifications.

- Variety of Shapes: Beyond the typical bar and block configurations, neodymium magnets can be shaped into cylinders, rings, or specialized forms to integrate seamlessly into specific machinery or devices.

- Hole Drilling: For applications that require mounting, neodymium bar magnets can be customized with drilled holes or specific cavities, facilitating easy installation and secure attachment.

- Magnetization Direction: Tailor the magnetization direction of your neodymium bar magnets according to your application's needs. Options include magnetizing through thickness, diameter, or configured with multiple poles.

- Coating Options: Choose from a range of coatings for your neodymium bar magnets, such as nickel, epoxy, or plastic, to enhance durability and resistance to environmental factors.

- Scalable Production: Whether you need a few specialized neodymium bar magnets for a specific project or large quantities for industrial use, customization is scalable to match your production needs.

- Expert Consultation: Leverage the expertise of manufacturers who specialize in neodymium bar magnets to ensure that your customized magnets meet your application’s exact demands.

In summary, the customization of neodymium bar and block magnets not only enhances their utility but also expands their applicability across various sectors. Whether you're involved in manufacturing, engineering, medical devices, or consumer electronics, customized neodymium bar magnets can be engineered to your specific requirements, providing tailored magnetic solutions where needed.

6. What Are the Temperature Limits for Neodymium Bar and Block Magnets?

Neodymium bar and block magnets, known for their strong magnetic capabilities and wide-ranging applications, also possess critical temperature limits. Understanding these limits is crucial for anyone utilizing these powerful bar magnets and strong bar magnets.

- Curie Temperature: Neodymium magnets, including bar and block types, have a pivotal temperature known as the Curie temperature (Tc). This temperature varies with the grade of the magnet, typically between 310 to 380 degrees Celsius (590 to 716 degrees Fahrenheit) for standard N-grade neodymium magnets. Exposure to temperatures at or above this level can cause the magnets to lose their magnetization permanently, undermining their strength and utility.

- Maximum Operating Temperature: Beyond the Curie temperature, neodymium bar magnets have a maximum operating temperature (Tmax) which is less than the Curie temperature but crucial for practical applications. For most N-grade neodymium magnets with standard nickel coating, this maximum operating temperature is generally within 80 to 150 degrees Celsius (176 to 302 degrees Fahrenheit). Exceeding this temperature can result in a decline in magnetic performance and potential demagnetization.

For applications that demand exposure to higher temperatures, it may be necessary to explore alternatives such as samarium cobalt magnets, which are better suited to such environments. Additionally, implementing protective measures like thermal insulation or cooling strategies can be vital in preserving the integrity of neodymium bar magnets under elevated temperatures.

In conclusion, while neodymium bar and block magnets are indispensable for their exceptional magnetic strength, their performance is temperature-sensitive. Familiarity with their Curie and maximum operating temperatures is essential to ensure their effective and reliable use across diverse applications. Consulting with magnet experts or manufacturers is recommended to choose the most appropriate magnet material based on specific thermal conditions.

7. Where Can I Purchase Neodymium Bar and Block Magnets?

If you're in search of neodymium bar and block magnets for your specific needs, you have several options available to you. Neodymium magnets, renowned for their incredible strength and versatility, can be sourced from a variety of outlets:

1. Online Retailers: CMS Magnetics Inc. offers a wide selection of neodymium bar and block magnets. While you can also find them on popular e-commerce platforms like Amazon, eBay, and Alibaba, it's important to be cautious, as some offerings on these platforms may be of lower quality or have weaker magnetic properties.

2. Specialty Magnet Stores: Some stores specialize in magnets and magnetic products. These establishments typically carry a diverse range of neodymium magnets suitable for various applications. You can locate them by searching online or consulting local business directories.

3. Local Hardware Stores: Depending on your location, you may find neodymium bar and block magnets at nearby hardware stores or home improvement centers. Although the selection might be more limited compared to online sources, these stores can be convenient for immediate needs. However, be aware that such stores often offer magnets of lower quality and reduced magnetic strength.

4. Industrial Suppliers: If you require neodymium magnets for industrial or large-scale applications, consider contacting industrial suppliers or manufacturers. They can provide customized solutions and bulk quantities tailored to your specific requirements.

5. Craft and Hobby Shops: Neodymium magnets are also used in crafting and DIY projects. Craft and hobby shops may stock small neodymium bar and block magnets suitable for creative endeavors. Keep in mind that magnets found in these shops might have lower quality and magnetic strength compared to specialized suppliers.

When shopping for neodymium bar and block magnets, take into account factors such as the specific type, size, grade, and quantity needed for your project or application. Additionally, read customer reviews and ratings when making online purchases to ensure product quality and reliability.

Always exercise caution when handling neodymium magnets, as they are extremely potent and can pose safety risks if mishandled. Keep them out of reach of children and adhere to safety guidelines to prevent accidents.

Whether your need for neodymium bar and block magnets arises from scientific experiments, industrial applications, crafting, or any other purpose, exploring these purchasing options should help you find the magnets that best suit your requirements.

8. What Are the Coating Options for Neodymium Magnets?

Neodymium magnets, whether they are bar, block, or rectangular in shape, can be coated with various materials to enhance their durability, resistance to corrosion, and overall performance. These coating options are essential to protect the magnet material from deterioration due to environmental factors. Here are some common coating options for neodymium magnets:

1. Nickel-Copper-Nickel (Ni-Cu-Ni): This is one of the most popular and widely used coatings for neodymium magnets. It provides excellent corrosion resistance and durability, ensuring that the magnet retains its strength and integrity over time. Ni-Cu-Ni-coated magnets are suitable for a wide range of applications, including industrial, scientific, and commercial uses.

2. Epoxy Resin: Neodymium magnets can also be coated with epoxy resin, which forms a protective layer around the magnet. Epoxy-coated magnets are ideal for applications where exposure to moisture or harsh chemicals is a concern. The epoxy coating provides an additional level of protection against corrosion.

3. Zinc (Zn): Zinc coating is another option for neodymium magnets. It offers good corrosion resistance and is often used in outdoor or marine applications. Zinc-coated magnets are known for their ability to withstand exposure to moisture and humid conditions.

4. Plastic or Rubber Coating: In some cases, neodymium magnets may be coated with plastic or rubber materials. These coatings provide insulation and protection against damage, making them suitable for applications where the magnet may come into contact with delicate surfaces or materials.

5. Gold (Au): Gold plating is an option for neodymium magnets when a high level of corrosion resistance and aesthetics are required. Gold-coated magnets are commonly used in medical devices, precision instruments, and jewelry applications.

6. Phosphating: Phosphating is a coating method that involves the application of a phosphate layer to the magnet's surface. It enhances adhesion when the magnet is bonded to other materials or components.

The choice of coating depends on the specific application, environmental conditions, and desired properties. Neodymium magnets come in a variety of coating options to ensure they perform optimally in diverse settings. When selecting a coated neodymium magnet, consider the factors that are most important for your particular use case, such as resistance to moisture, chemicals, or temperature extremes.

9. Can I Use Neodymium Magnets in High-Temperature Environments?

Neodymium magnets, including bar, block, and rectangular varieties, are known for their exceptional strength and versatility. However, they do have limitations when it comes to high-temperature environments. Neodymium magnets are sensitive to temperature, and their performance can be significantly affected by exposure to elevated temperatures.

The temperature resistance of neodymium magnets primarily depends on their grade. Neodymium magnets are available in various grades, with the most common ones being N35, N42, N45, N48, N50, and N52. The higher the grade, the better the temperature resistance. However, even the highest-grade neodymium magnets have their limits.

Here's a general guideline for the temperature limits of neodymium magnets:

1. N35 to N42 Grade: These magnets typically have a maximum operating temperature of around 80°C (176°F). Exposure to temperatures above this limit can result in a loss of magnetism and reduced magnetic strength.

2. N45 to N52 Grade: Higher-grade neodymium magnets offer better temperature resistance, with maximum operating temperatures of approximately 100°C to 150°C (212°F to 302°F). They can withstand higher temperatures for short durations.

It's crucial to note that these temperature limits are general guidelines, and actual performance may vary depending on factors such as magnet size, shape, and exposure time. Additionally, rapid temperature changes can impact neodymium magnets, so gradual heating or cooling is recommended.

For applications that involve high-temperature environments exceeding the recommended limits, alternative magnet materials like samarium cobalt (SmCo) magnets or alnico magnets may be more suitable. These materials offer better temperature resistance but may come at a higher cost.

In summary, while neodymium magnets are incredibly strong and versatile, their use in high-temperature environments should be carefully considered, and the appropriate grade should be selected based on the specific temperature requirements of your application.

10. How to Separate Rectangular or Bar Neodymium Magnets?

Separating rectangular neodymium magnets, especially when they're not equipped with plastic separators, can indeed be a challenging task due to their remarkable strength. To safely separate them, follow these steps:

- Gather Your Tools: You'll need two flat, non-magnetic objects with smooth edges. Materials like plastic or wood work best. Avoid using steel tools as they can easily attract the magnets.

- Protect Yourself: Wear thick gloves and safety goggles to safeguard your hands and eyes from potential pinching and accidents.

- Prepare Your Workspace: Choose a clean, flat, and non-magnetic surface, such as a wooden table, as your workspace. Ensure there are no metal objects nearby that could interfere with these bar magnets.

- Position the Bar Magnets: Place the bar magnets you want to separate on the edge of the table. If there is a separator between them, ensure the separator is resting on the table, but let the bar magnet to the right of the separator hang off the edge.

- Slide and Separate: Assuming you're right-handed, use your left hand to firmly hold the separator and the magnet on the left side of the separator against the table. Then, use your right hand to press down on the bar magnet to the right of the separator. Apply steady and even pressure until the magnets separate. Keep them apart until you're sure they won't attract each other again.

- Store Safely: After successfully separating the bar magnets, handle them with care. Store them individually or with a non-magnetic material placed between them to prevent accidental attraction.

Always remember that neodymium rectangular magnets are extremely powerful, and there's a risk of pinching if you're not cautious. Take your time, follow the steps carefully, and prioritize safety when working with these super-strong magnets. If you have any doubts or are dealing with exceptionally large or potent rectangular magnets, seek assistance from someone experienced in handling them. Safety should be your utmost concern when working with bar neodymium magnets.

The Neodymium Bar Magnets at CMS Magnetics & Magnets for Sale

Discover the power and versatility of Neodymium Bar Magnets, the exceptional magnetic wonders that will leave you in awe. At Magnets For Sale & CMS Magnetics, we offer a wide range of these super-strong magnets that come in various sizes to suit your specific needs.

Our Neodymium Bar Magnets are available in sizes ranging from less than ¼ inch in diameter to well over 2 inches across. What makes them even more practical is the inclusion of a countersunk hole already drilled in the middle. This hole allows you to easily attach the magnet to non-metallic materials like wood or plastic. The ingenious design ensures that the screw's head sits flush with the face of the magnet, preventing any interference with its function.

These Neodymium Bar Magnets introduce you to the fascinating world of magnetics that seemingly defy the laws of physics. Whether you're a scientist, DIY enthusiast, or industrial professional, there's a Neodymium Bar Magnet for you. We offer a variety of grades, including N35, N42, N45, N50, and N52. With physical sizes ranging from less than ¼ inch to over 4 inches in length, these little marvels of science pack a punch.

In our selection, you'll find Neodymium Bar Magnets with epoxy coatings for added durability and longevity. The countersunk hole feature makes them even more versatile, essentially doubling their usefulness. You can count on these magnets to securely attach to non-metallic surfaces without any hassle.

Experience the captivating world of Neodymium Bar Magnets at Magnets For Sale & CMS Magnetics. Whether you're looking for strength, versatility, or both, these magnets have you covered.