Shop By Category

- Hot Deal

-

Neodymium Magnets

- Neodymium Magnets

-

DISC Magnets

- DISC Magnets

- Disc Neodymium Magnets Diameter <= 1/4"

- Disc Neodymium Magnets 1/4 < Diameter <= 1/2"

- Disc Neodymium Magnets 1/2 < Diameter <= 1"

- Disc Neodymium Magnets Diameter > 1"

- Diametrically Magnetized Magnets

- Countersunk Disc Magnets

- Adhesive Disc Magnets

- Plastic Coated Disc Magnets

- Steel Magnet Strikers

- BAR Magnets

- Cylinder Magnets

- RING Magnets

- CUBE Magnets

- ARC Magnets

- WEDGE Magnets

- Magnet Sphere

- Plastic Coated Magnets

- Magnet Strikers

- N52 Neodymium Magnets

- CERAMIC Magnets

- SmCo Magnets

- ALNICO Magnets

- Cup & Pot Magnets & Magnetic Bases

-

Home Magnets

- Rubber Coated

- OFFICE Magnets

- Industrial Magnets

- Magnet Wires

- Custom Made Magnets

- Amazon Neodymium Magnets

- WIND POWER - Blades

Shop By Brand

- Neodymium Magnets

-

DISC Magnets

- DISC Magnets

- Disc Neodymium Magnets Diameter <= 1/4"

- Disc Neodymium Magnets 1/4 < Diameter <= 1/2"

- Disc Neodymium Magnets 1/2 < Diameter <= 1"

- Disc Neodymium Magnets Diameter > 1"

- Diametrically Magnetized Magnets

- Countersunk Disc Magnets

- Adhesive Disc Magnets

- Plastic Coated Disc Magnets

- Steel Magnet Strikers

- BAR Magnets

- Cylinder Magnets

- RING Magnets

- CUBE Magnets

- ARC Magnets

- WEDGE Magnets

- Magnet Sphere

- Plastic Coated Magnets

- Magnet Strikers

- N52 Neodymium Magnets

Shop By Brand

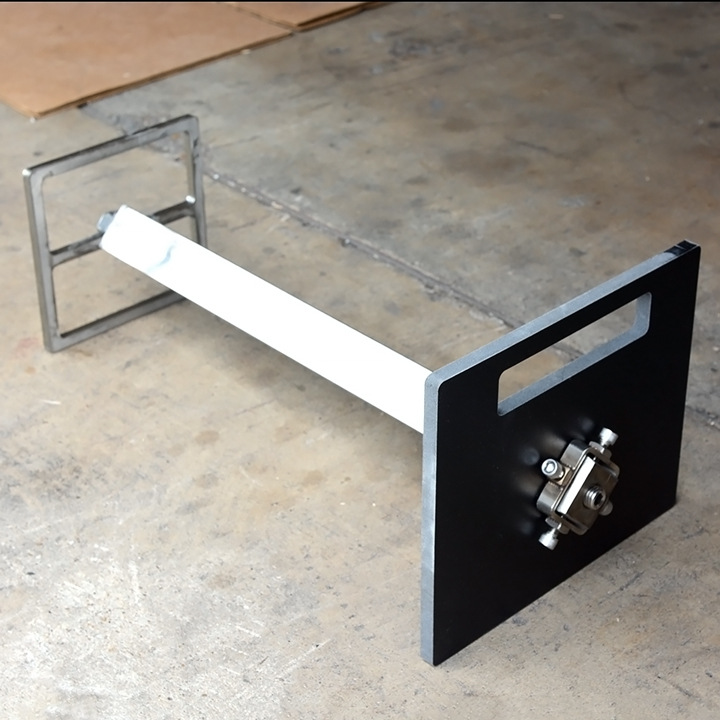

DITCH Magnets

Premium Neodymium Ditch Magnets for Oilfield Drilling

Neodymium Ditch Magnets, engineered to significantly improve the extraction of magnetic particles from drilling mud in oilfield operations. Our ditch magnets leverage the exceptional magnetic properties of Neodymium, offering a solution that is eight times more effective than conventional ceramic magnets.

Key Advantages of Neodymium Ditch Magnets:

- Enhanced Magnetic Performance: Utilizing Neodymium, these magnets provide unparalleled magnetic strength, ensuring thorough particle capture for cleaner drilling fluid.

- Operational Efficiency: Despite their advanced capabilities, our Neodymium Ditch Magnets are priced competitively, delivering enhanced efficiency and cost savings over traditional options.

- Ease of Use and Maintenance: Designed with practicality in mind, these magnets are lightweight and come with a user-friendly cleaning mechanism, facilitating simple maintenance.

- Customizable Leasing Solutions: Recognizing diverse operational needs, CMS Magnetics offers flexible leasing options, allowing for scalable and budget-conscious deployment.

Technical Specifications and Applications

Manufactured to ISO 9001 quality standards, our Neodymium Ditch Magnets are encapsulated in a corrosion-resistant coating, ensuring durability in demanding oilfield environments. Their superior design guarantees reliability and longevity, making them an indispensable tool for enhancing drilling operations.

Why Choose CMS Magnetics?

CMS Magnetics is at the forefront of magnetic technology in the oilfield industry, providing innovative solutions that drive efficiency and performance. Our Neodymium Ditch Magnets represent our commitment to excellence, offering an effective alternative to traditional drilling equipment.

Frequently Asked Questions: Ditch Magnets in Oilfield Drilling

1. What are Ditch Magnets?

Ditch Magnets are specialized magnetic devices engineered for use in the oil and gas industry, especially in drilling operations. Their main function is to efficiently capture and extract ferrous metal debris from drilling fluids, thereby safeguarding drilling equipment and enhancing operational smoothness.

2. How do Ditch Magnets enhance drilling operations?

In the context of drilling, Ditch Magnets are strategically positioned within the fluid pathway to magnetically attract and secure metal fragments and shavings. This process prevents these particles from re-entering the circulation system, thus protecting the drilling equipment from potential damage and maintaining operational integrity.

3. Why are Ditch Magnets critical for oilfield operations?

Ditch Magnets play a pivotal role in preserving the functionality and efficiency of drilling equipment. By effectively removing metallic debris, they significantly reduce the wear on critical components, like drill bits and pumps, minimize downtime risks, and bolster safety measures in drilling environments.

4. What types of debris do Ditch Magnets capture?

These magnetic tools are adept at capturing various forms of ferrous debris, such as metal shavings, nails, screws, and other small metal objects that may detach during drilling activities, ensuring cleaner and safer operation.

5. Are various Ditch Magnets available for different drilling scenarios?

Indeed, Ditch Magnets are available in an array of sizes and magnetic strengths to suit diverse drilling requirements and fluid volumes. Selection is typically based on the specific parameters of the drilling operation, including well depth and diameter.

6. Maintenance and cleaning practices for Ditch Magnets?

For optimal functionality, it is essential to regularly clean Ditch Magnets by removing trapped metal debris and conducting thorough inspections for wear or damage. This routine ensures sustained effectiveness and longevity.

7. What is the durability of Ditch Magnets in oilfield settings?

The operational lifespan of Ditch Magnets is influenced by factors such as usage frequency and adherence to maintenance protocols. With diligent care, these magnets can effectively serve multiple drilling projects.

8. Can Ditch Magnets be tailored for unique drilling needs?

CMS Magnetics and Magnets for Sale provide customization services for Ditch Magnets, offering various dimensions, strengths, and configurations to meet specific drilling conditions and objectives.

9. Purchasing Ditch Magnets for drilling operations?

Specialized suppliers like CMS Magnetics and Magnets for Sale are your go-to sources for purchasing Ditch Magnets. They offer a broad selection tailored for oilfield applications, with customization options available to meet specific drilling requirements.

10. Environmental considerations of using Ditch Magnets?

Employing Ditch Magnets is a practice aligned with environmental stewardship. They play a crucial role in maintaining cleaner drilling operations and reducing the environmental footprint associated with drilling activities.